Visible to Intel only — GUID: amv1693244341253

Ixiasoft

Visible to Intel only — GUID: amv1693244341253

Ixiasoft

8.5.1. PCB Stack-up and Design Considerations

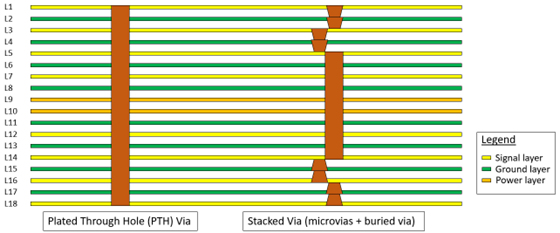

A high-quality type-IV PCB with higher cost uses not only plated-through-hole (PTH) vias to connect from the top to bottom layer, but also stacked vias, micro vias, and buried vias to connect between layers. The following figure shows a cross-sectional comparison of a PTH and stacked via.

To support maximum data rate operation, LPDDR5 board design requires a high-quality PCB stackup using backdrill or micro vias, buried vias, or stacked vias to reduce crosstalk for high performance. Reducing the length of signal via is essential to minimize the crosstalk between signals.