|

Click an image to download high resolution versions

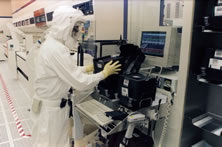

Checking wafers processing in a vertical diffusion furnace, one of the many tools through which wafers must pass as they go through the hundreds of steps that make up the manufacturing process. (400dpi tif - 10.6 MB) |

Clean air continuously flows from every pore of the ceiling and through the holes in the floor. All of the air in the clean room is replaced several time every minute. (400 dpi tif - 16.4 MB) |

A technician checks individual wafers, which can contain hundreds of individual chips, to make sure they are perfect. (400dpi tif - 16.4 MB) |

Close up of the wafer as it spins during a testing procedure. (400dpi tif - 16.4 MB) |

Intel technicians monitor the wafers' progress through the Fab using automated measurement tools and strict quality standards. (400dpi tif - 10.6 MB) |

Intel Fab workers don Gore-Tex® semi-custom-fitted bunnysuits that must be worn in the Fab cleanroom. (300dpi tiff - 1.6Mb) |

An Intel technician holds a wafer for the camera. Each square on the wafer is called a "die" and each microprocessor will eventually become the "brain" of a PC system. (400dpi tif - 16.4 MB) |

Intel technicians monitor wafers in an automated wet etch tool. The process cleans the wafers of any excess process chemicals or contamination. (400dpi tif - 10.6 MB) |

|

|

|