Processor Integration Overview for LGA115x-based Intel® Processors

The following overview and installation instructions are for professional system integrators building ATX form factor PCs that use Intel® Boxed Processors in the LGA115x-land package with industry-accepted motherboards, chassis, and peripherals. It contains technical information intended to aid in system integration.

Visit the Intel® Processor Installation Center for more material on LGA115x-based installation.

| Note | This integration documentation refers to the installation of both LGA1156-based processors and fan heat sinks and LGA1155-based processors and fan heat sinks due to the similarity between the two installations. The same fan heat sinks may be used across the two sockets if the Thermal Design Profile (TDP) of the processor is the same. The fan heat sink installation is identical across both sockets. Be aware that LGA1156- and LGA1155-based processors are not compatible between sockets due to electrical, mechanical, and keying differences. You risk damaging either the processor or the socket if you try and install a LGA1156-based processor in a LGA1155 socket or vice versa. |

Click or the topic for details:

Handling procedures

Motherboard handling

- Remove motherboard from ESD bag (if applicable).

- Make sure socket load lever and load plate are secured. Do not open socket at this time.

- Inspect to ensure socket protective cover is present and properly secured. Do not remove socket protective cover.

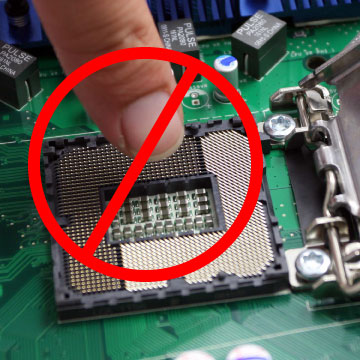

- Do not touch socket sensitive contacts (see image below).

Socket preparation

Opening the socket

- Disengage load lever by releasing down and out on the hook. This will clear retention tab.

- Rotate load lever to open position at approximately 135°.

- Rotate load plate to open position at approximately 150°.

Note Apply pressure to the corner with your right-hand thumb when opening or closing load lever. Otherwise, the lever bounces back causing bent contacts.

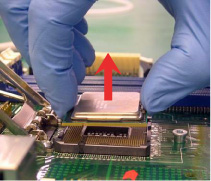

Removing the socket protective cover

| Note | We do not recommend vertical removal, as it requires higher force and can lead to socket contact damage. |

- Place thumb against the front edge of the protective cover and rest index finger on the rear grip to maintain control of the cover.

- Lift the front edge of the protective cover to disengage from the socket. Keep control of the cover by holding the rear grip with index finger.

- Lift protective cover away from the socket, being careful not to touch the electrical contacts.

Caution

Never touch fragile socket contacts to avoid damage.

Inspecting for bent contacts

Inspect socket contacts from different angles to make sure none are damaged. If any are damaged, do not use the motherboard.| Note | If any socket or motherboard is suspected of being mishandled, the socket should be examined. |

Five types of contact damage to look for (see Table 1 below for potential causes and solutions):

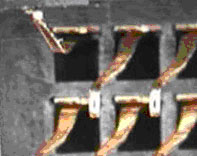

- Contact is bent backwards upon itself (see Figure 1).

- Content is bent forward or downward (see Figure 2).

- Contact is bent sideways (see Figure 3).

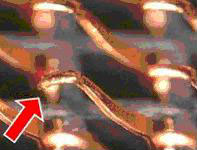

- Contact tip is bent up (see Figure 4).

- Contact tip is missing (same as Figure 4).

Figure 1: Contact is bent backwards upon itself | Figure 2: Contact is bent forward or downward |

Figure 3: Contact is bent sideways | Figure 4: Contact tip is bent up or missing |

Table 1: Bent contact causes and corrective actions

| Failure Type | Potential Causes | Possible Corrective Action |

| 1,5 | CPU tilted during installation or removal Glove/finger snag | Verify CPUs are installed and removed vertically ONLY Vacuum wands may be considered Verify CPUs are being held by the substrate edge ONLY |

| 1,5 | Glove/finger snag CPU capacitors dragging | Verify packages are held by substrate edges ONLY Verify CPUs are lifted and placed vertically ONLY Vacuum wands may be considered |

| 2 | CPU tilted during installation or removal CPU dragged across contacts during installation or removal CPU dropped during installation or removal Socket protective cover dropped into socket | Verify packages are held by substrate edges ONLY Verify CPUs are lifted and placed vertically ONLY Vacuum wands may be considered |

| 3 | CPU tilted during installation or removal CPU dragged across contact array Glove/finger snag | Verify packages are held by substrate edges ONLY Verify CPUs are lifted and places vertically ONLY Vacuum wands may be considered |

| 4 | Socket supplier defect Glove/finger snag CPU capacitors dragging Return motherboard to manufacture | Verify packages are held by substrate edges ONLY Verify CPUs are lifted and places vertically ONLY Vacuum wands may be considered |

Boxed Intel® Processor installation

Processor handling

- Open boxed processor packaging.

- Inspect to ensure processor protective cover is present and properly secured. Do not remove processor protective cover.

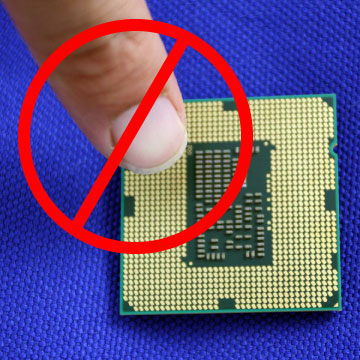

- DO NOT TOUCH PROCESSOR SENSITIVE CONTACTS AT ANY TIME DURING INSTALLATION:

Processor installation

- Lift processor package from shipping media by grasping the substrate edges:

- Scan the processor package gold pads for any presence of foreign material. If necessary, the gold pads can be wiped clean with a soft lint-free cloth and isopropyl alcohol.

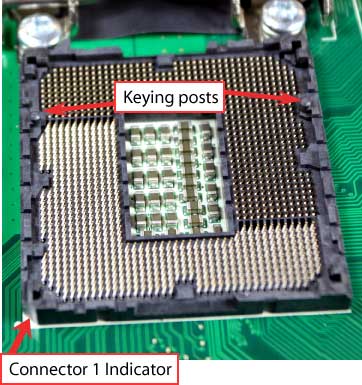

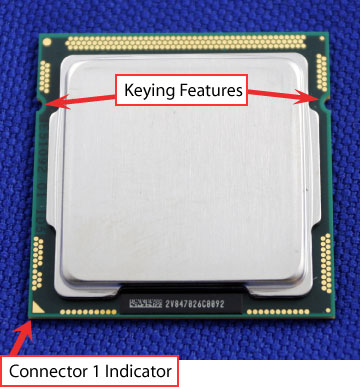

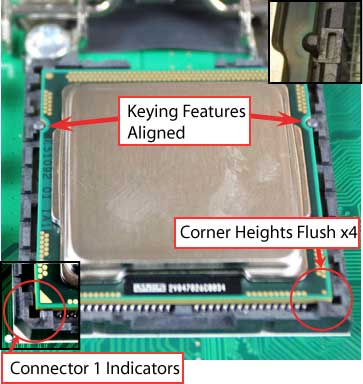

- Locate connection 1 indicator on the processor which aligns with connection 1 indicator chamfer on the socket, and notice processor keying features that line up with posts along socket walls:

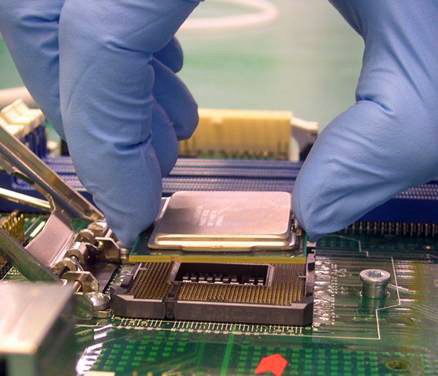

- Grasp the processor with thumb and index finger along the top and bottom edges. (Do not touch the Orientation Notches.) The socket will have cutouts for your fingers to fit into (see image below).

- Carefully place the processor into the socket body vertically (see image below).

Note Tilting or roughly shifting it into place can damage socket contacts. Caution

Do not use a vacuum pen for installation.

- Verify that package is within the socket body and properly connected to orientation keys.

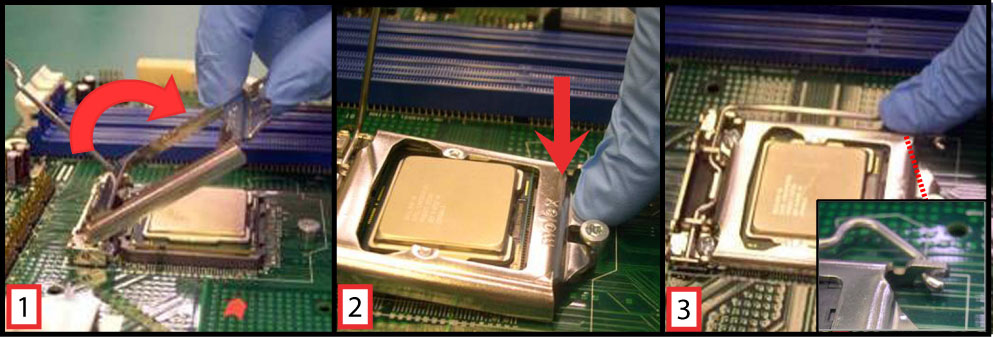

- Close the socket (see image below):

- Gently lower the load plate.

- Make sure load plate's front edge slides under the shoulder screw cap as the lever is lowered.

- Latch the lever under the top plate's corner tab, being cautious not to damage the motherboard with the tip of the lever.

Fan heat sink handling

- To prevent damage, avoid setting the thermal solution with the prongs down.

- Set on side or with fan down:

Fan heat sink installation

| Note | The thermal solution integration procedures should be performed with the motherboard in the chassis to provide proper clearance under the motherboard for the fastener mechanisms. |

- Install the motherboard into the chassis.

Note Thermal solutions that come with the Boxed Intel® processor use pre-applied thermal interface material (TIM) and do not need grease. Caution

Do not to touch or disturb the TIM on the heat sink during installation. If the TIM is disturbed contact customer support. - Remove heat sink from packaging.

- Place heat sink onto the LGA115x socket.

- Ensure fan cables are on side closest to fan header.

- Align fasteners with MB through-holes.

- Make sure fasteners are flush with motherboard with the following steps (see image below).

Inspection 1

- Ensure cables are not trapped or interfering with fasteners.

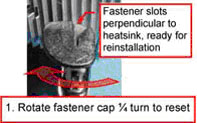

- Ensure fastener slots are pointing perpendicular to heat sink (see image below).

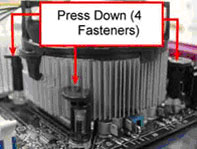

Actuate fasteners (see image below):

- While holding heat sink, press down on fastener caps with thumb to install and lock.

- Repeat with remaining fasteners.

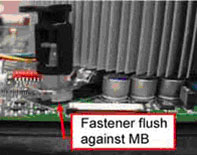

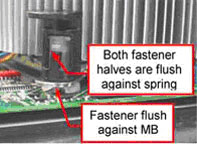

Inspection 2 (see image below):

- Pull on fasteners to verify they are properly seated.

- Ensure both fastener cap and base are flush with spring and motherboard and MB.

- Connect fan cable to Board CPU header (see image below).

- Secure excess cable with tie-wrap to ensure cable does not interfere with fan operation or contact other components.

Boxed Intel Processor removal

Removing the boxed processor fan heat sink

| Note | Be sure to take the proper electrostatic discharge (ESD) precautions (ground straps, gloves, ESD mats, or other protective measures) to avoid damaging the processor and other electrical components in the system. |

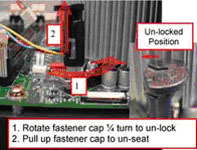

Follow these steps to remove the boxed processor fan heat sink from the system (see image below):

- Disconnect fan cable from motherboard header.

- Turn fastener caps (1) counter-clock wise 90° to the un-locked position. (You may need to use a flathead screwdriver to unlock the fasteners.)

- Pull up on fastener caps to unseat.

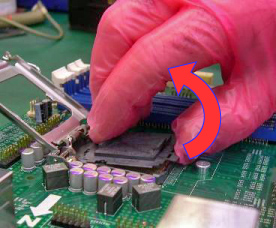

- Manually remove heat sink with gentle twisting motion.

Note To re-assemble the heat sink, reset the fastener caps to their original position with the slot perpendicular to the heat sink. Re-attach cable to cable management clips. Then, follow the assembly instructions (see image below).

Note Every time the heat sink is removed from the processor, it is critical that the thermal interface material be replaced, in order to ensure proper thermal transfer to the boxed processor fan heat sink.

Removing the processor

- Open the socket:

- Disengage the load lever.

- Open the load plate.

- Remove the Processor package, holding along the top and bottom edges, or by using a vacuum pen.

- Maintain Processor horizontal and remove Processor with a vertical motion to avoid damaging the socket contacts.

- Place the processor in a specially designed tray or ESD retainer for storage. Do not place directly on table resting on gold lands.

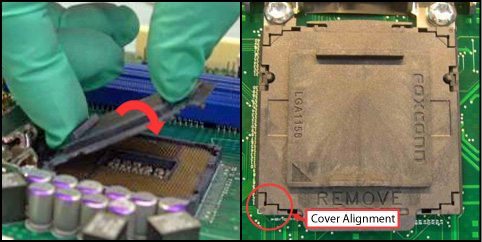

- Assemble LGA115x socket protective cover:

- Hold protective cover at 45 degree angle to the LGA115x Socket

- Carefully lower protective cover on hinge side first, to contact with the outside wall of the LGA115x Socket:

- Engage protective cover retention features to outside of LGA115x Socket, AND align 2 cover corners to socket corners (This step is critical to avoid Bent Contact Damage!)

- Lower protective cover to attach to the LGA115x Socket on Shoulder screw side

- Perform Visual and Tactile verification that protective cover is properly seated in the LGA115x Socket:

- Hold cover and move gently side-to-side to feel the play within the cover and the LGA115x Socket

- Close the socket load plate and engage the load lever: