SEIT* autonomous mobile robots, running on Intel® technology, enable manufacturers to improve flexibility and efficiency of intralogistics transportation.

Executive Summary

To remain competitive, manufacturers must focus on achieving new growth while driving down costs. Key to achieving this is greater flexibility and a dramatic upturn in operational efficiency across the manufacturing process. One area ripe for improvement is intralogistics transportation.

Many manufacturers still rely on autonomous guide vehicles (AGVs) to undertake repetitive transport tasks; but, rigid in nature, they do not support today’s demand-driven, dynamic manufacturing environments. Intelligent autonomous mobile robots (AMRs), like SEIT* from Milvus Robotics, offer a viable and cost-effective alternative.

This solution brief describes how to solve business challenges through investment in innovative technologies.

If you are responsible for…

-

Business strategy:

You will better understand how autonomous mobile robots will enable you to successfully meet your business outcomes. -

Technology decisions:

You will learn how an autonomous mobile robot solution works to deliver IT and business value.

Figure 1. SEIT AMR from Milvus Robotics

Solution Benefits

- Efficient operation - Fully autonomous rather than automated, SEIT* AMRs choose and decide the best route to take to optimize workflow and travel time.

- Safe navigation - SEIT AMRs have the intelligence to navigate safely around people and objects with LiDAR and some additional sensors, and a built-in collision avoidance system.

- Fast deployment - Do not depend on any physical infrastructure like wires or tapes meaning common failures like gaps in track lines do not occur, costs are reduced and robots can be up and running in just couple of hours.

Succeeding in a Fiercely Competitive Sector

Manufacturers operate in a highly challenging market segment. In some low-cost labor countries, wage rates are rising rapidly. Volatile resource prices, a looming shortage of highly skilled talent, and heightened supply-chain and regulatory risks create an environment that is far more uncertain than it was before the Great Recession1.

At the same time, customer expectations are rising and demand for high-quality customized products and services is greater than ever. To compound matters, competition in the manufacturing sector is fierce, particularly within and from Asia. Manufacturers must remain highly focused on achieving new growth and driving down costs to remain competitive.

To realize these ambitions, manufacturers need to dramatically improve operational efficiency. Inflexible legacy equipment struggles to respond quickly to consumer demand and sometimes unpredictable disruptions. Investing in digital technologies is crucial for driving down costs and creating demand-driven and responsive business models.

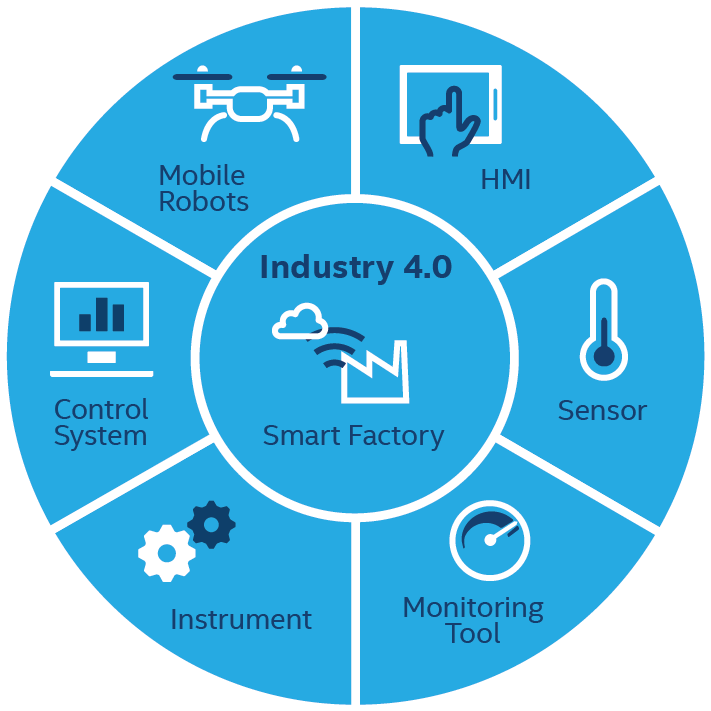

Industry 4.0, the latest phase in the digitization of the manufacturing sector, is creating new ways for manufacturers to deliver value. Harnessing the power of the Internet of Things (IoT), manufacturers can now automate and track every step of their production from the receipt of raw materials all the way through to delivery at the customer. They can monitor, collect, process and analyze huge volumes of data every step of the way. From this data, they can then derive insight to improve operational efficiency and productivity, increase flexibility and agility, and ultimately drive down costs.

Streamlining Intralogistics Transportation

Manufacturers work hard to optimize, automate and integrate the logistical flow of materials within the walls of their fulfillment centers, distribution centers, and warehouses. While some still rely on traditional methods of transportation – forklifts and pallets – many have sought to improve intralogistics by rolling out AGVs.

AGVs reduce the need for workers to carry out non-value add activities on the shop floor by undertaking repetitive transportation jobs. They follow magnetic or optical wires dug into the floor or take reference from reflectors placed on the walls and can tow objects behind them or carry materials on a bed. AGVs are used in nearly every industry, including pulp, paper, metals, newspaper, and general manufacturing.

While they offer many benefits, AGVs require large upfront infrastructure investment and are limited to predefined routes as they need fixed references to operate, all of which brings an innate rigidness. Today’s factories, however, are far from static. As manufacturers adapt to meet customers’ ever-changing desires and needs, flexibility is critical. AGVs, unfortunately, are unable to provide this. More recently AGV’s inability to keep up with the demands of the dynamic factory environment led to a surge in human intervention, which in turn, led to an increase in transportation costs. Manufacturers needed another solution.

Solution Value: Agile, Cost-effective, Autonomous Transportation

Using the sensory and processing powers enabled through Industry 4.0, SEIT AMRs from Milvus Robotics provide a much more flexible, efficient and integrated transportation compared to AGVs. Autonomous rather than automated, SEIT AMRs have the intelligence to decide and act according to changing environmental conditions. They choose and decide the best routes to take to optimize workflow and travel time, and can safely navigate around obstacles.

Capable of sharing a space with human workers, SEIT AMRs can integrate with existing management systems, and take orders from them. They can also communicate with robotic arms or a conveyor to undertake loading and unloading. Multiple SEIT AMRs can work harmoniously in the same facility, thanks to vehicle tracking and/ or fleet management systems. The best robot is selected for the job according to already programed jobs, distance to destination, and battery level. Thus, throughput can be optimized in facilities where there would otherwise be bottlenecks.

As they map the environment in which they are working in by a process of natural navigation, they do not need any sort of bands, rails or any other infrastructure investments. They can be up and running in a couple of hours. Technicians just need to create a map, define destination points and construct workflows. This process doesn’t require any third-party vendor intervention or additional training.

Built with industrial grade components, SEIT AMRs are designed to withstand the rigors of industrial environments and can safely handle payloads up to 1500 kg with a maximum speed of 1.5 m/s and a zero turning radius.

SEIT AMRs are controlled via Milvus Fleet Manager*, a Web-based platform built on RESTful* API, that allows users to request data, form new jobs and mission flows, and trigger actions by using any automation platform. It is the main interface to communicate with machines grouped as M2M network. Any authorized person can access the controls from any WiFi-connected device such as cell phone, tablet or computer. They can get real-time information and connect to the rest of the facility production orchestra players to create a fully trackable flow to optimize productivity. Factories can also create their own custom application modules for communication, data transfer, and tracking over internet, including conditional dynamic operations.

Depending on the implementation, AMRs can provide a return on investment after just one or two years, as they increase productivity, streamline operations, reduce accidents and eliminate CAPEX.

Manufacturers from all sectors from FMCG and home appliances, from Turkey to the United States, have rolled out SEIT AMRs.

Solution Architecture: SEIT AMRs, Running on Intel® Technology

Figure 2. SEIT AMRs, running on Intel® technology, improve operational efficiency

Milvus Robotics collaborates with Intel to optimize the operation of its SEIT AMRs.

SEIT AMRs use 2D Light Detection and Ranging (LiDAR) to underpin some safety elements but alone it is not enough. To ensure 3D space detection, each robot is also kitted out with Intel® RealSense™ technology. This provides the robot with computer vision so it can recognize objects or people while navigating fulfillment centers, distribution centers, and warehouses.

Conclusion

Manufacturers tasked with keeping pace with ever-changing customer demands for new and personalized products and services, while driving down costs, are looking for ways to increase agility and streamline operations.

Intralogistics transportation has relied on the use of AGVs for nearly fifty years, but they no longer support increasing requirements for highly adaptive manufacturing processes. Cognitive and capable of delivering dynamic and efficient transport in increasingly congested industrial operations, AMRs present a viable and cost-effective alternative to traditional material-handling systems like AGVs.

Solutions Proven By Your Peers

Intel Solutions Architects are technology experts who work with the world’s largest and most successful companies to design business solutions that solve pressing business challenges. These solutions are based on real-world experience gathered from customers who have successfully tested, piloted, and/or deployed these solutions in specific business use cases. Solutions architects and technology experts for this solution brief are listed on the front cover.

Learn More

Solution product company:

Intel products mentioned in the paper:

Find Out How You Could Harness the Power of the Internet of Things

Find the solution that is right for your organization. Contact your Intel representative or visit Intel Internet of Things (IoT).